-40%

COMPLETE REBUILD SERVICE - EATON MODEL 6, EATON MODEL 7 HYDROSTATIC TRANSMISSION

$ 369.59

- Description

- Size Guide

Description

THIS LISTING IS FOR AREBUILD SERVICE

OF YOUR EATON MODEL 6 (CW, CCW) / EATON MODEL 7 (CW, CCW) HYDROSTATIC TRANSMISSION for Grasshopper, Walker, John Deere, Cub Cadet, Toro, Wheelhorse, and others.

***

FREE RETURN SHIPPING

IN THE UNITED STATES TO THE LOWER 48***

PLEASE READ DESCRIPTION CAREFULLY!

THIS IS A

COMPLETE REBUILD SERVICE

WHICH RESTORES THE POWER BACK TO THE HYDROSTAT. YOU SEND US YOUR HYDROSTAT, WE REBUILD IT, AND RETURN IT TO YOU WITH

FREE RETURN SHIPPING

.

PLEASE NOTE THAT THIS LISTING REQURES

YOU SEND US YOUR UNIT AND WE REBUILD IT

(i

f you need a unit immediately,

please check our other listing (9.99)

for our current inventory of units on hand)

I

F YOU DO NOT HAVE A REBUILDABLE HYDROSTAT TO SEND US

,

PLEASE CONTACT US

BEFORE PURCHASING

TO DISCUSS YOUR OPTIONS!

NOT SURE OF THE ROTATION

(CW or CCW) OF YOUR HYDROSTAT? KEEP READING TO FIND OUT HOW TO TELL!

Please make sure to read all

Buyer Shipping Instructions

below before shipping unit.

This configuration of hydrostats is for a smooth (keyed) output shaft, NOT for the splined version! If you have a splined output shaft, please contact us before purchasing.

Does my hydrostat need to be rebuilt?

Over time, these hydrostats wear and develop leaks (blow-by) as the tolerances between critical interfaces grow beyond acceptable limits set forth by the original manufacturer. As a result, loss of power is experienced on the unit, especially on hot summer days. Perhaps you have experienced one hydrostat not keeping up with the other on your machine (very common). Our rebuild service will restore the power your hydrostat, eliminate the leaks, as well as remediate other common issues experienced on these units.

Rebuild Process

Hydrostats sent by buyer

must be

in rebuild-able condition. Units are typically rebuild-able, except in the most extreme events (i.e. – unit is cracked or seized).

If you do not have a unit to send us, please contact us BEFORE PURCHASING to discuss your options!

We have been rebuilding these hydrostats for over 20 years and have been providing this service locally for over 15 years. During this time, we have noted that the wear characteristics are predominantly consistent for these hydrostats. Therefore, the standard rebuild process is as follows:

1.

Each unit is completely disassembled, inspected and cleaned.

2.

The pump and motor rotor bushings are inspected and measured with upgraded bushings installed (typical). In addition, both internal rotors are refitted with the correct ball clearances, thus bringing the clearances back into manufacturer specifications.

3.

Spindle shafts (pump and rotor sides) are measured and inspected. Spindle shafts are rarely ever worn except in extreme cases. If shaft is worn (very rare), you will be contacted about your options.

4.

Check valves are inspected for correct functionality and replaced when necessary

5.

ALL seals and gaskets are replaced BRAND NEW

6.

After assembly, each unit is run on the test stand under load to measure potential loss of performance as the unit temperature rises. Design operating temperature on these units is 180 degrees Fahrenheit, but we run them to 200 degrees Fahrenheit on the test stand in order to ensure proper operation.

Additional Service as Necessary:

We have rectified two additional problem areas of these units; early control shaft wear/leakage, and stripping of the input shaft spline:

If the control shaft spline is worn

- the wear prone control shaft bore in the aluminum housing is refitted with hard bronze bushings.

If

the input shaft spline shows signs of failure and/or excessive wear -

the input shaft spline is replaced with a much larger spline on the shaft

and

pump rotor.

NOTE: This service is

not required on all units

as not all units exhibit this condition.

Everything is professionally and meticulously done because we enjoy doing so. This work requires both the skill and the tools to work to clearances and maintain tolerances measured in tenths of a thousandth of an inch (.0001).

·

NOTE1

- Yearly oil change is required

(USE

MOBIL1 15W50

ONLY

)!!! We cannot emphasize this enough!

·

NOTE2

- the input shaft is in the aluminum housing, the output shaft is in the cast iron housing.

·

NOTE3

- directions on changing output shaft rotation are included as well as contact information for any questions you may have

·

NOTE4

- many people wonder about the differences between the Eaton Model 6 and Model 7. The ONLY difference is that the Model 7 has a design feature inside that reduces vibration on the control handlebar or control lever. The operator’s hands will not notice as much vibration. Speeds and power and dimensions are identical and

the two models are interchangeable

.

·

NOTE5

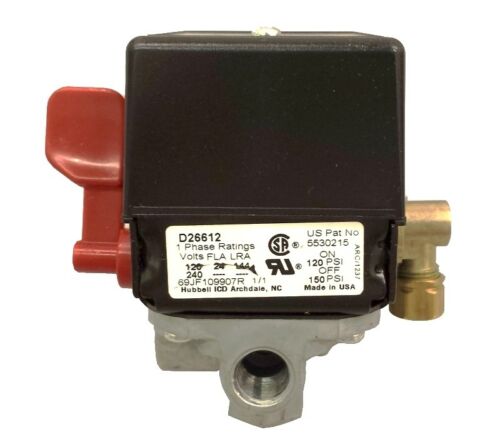

- the unit shown in the image is not the actual unit you will receive, but is an example of the high quality rebuilt unit you will receive from us.

How long will this rebuild process take?

In order to account for peak seasons, we have several units that have already been rebuilt and are ready for immediate shipment. THEREFORE, based on the current level of demand, you will receive EITHER:

·

The exact hydrostat you ship to us (completely rebuilt and tested)

OR

·

An exact replacement (completely rebuilt and tested).

This method allows us to provide the quickest service possible to our customers and is driven by the current level of demand. A typical rebuild takes

7-10 business days

once unit is received from the customer. If you have multiple units needing rebuilt, we recommend shipping them all at once to allow us to provide the quickest turnaround possible.

Buyer Shipping Instructions

Upon purchase of this rebuild service, we will contact you with our shipping info. You are responsible for the cost of shipping to us, but will receive

FREE RETURN SHIPPING

from us.

Buyer must ship unit

WITHIN 7 CALENDAR DAYS OF PURCHASE

.

If unit has not been shipped by buyer within 7 days of purchase of our service, sale will be cancelled.

To be clear, we are not asking that the unit arrives to our facility within 7 days of purchase of the service,

rather the unit must be

shipped

by buyer within 7 days of purchase of service.

After you ship your unit,

PLEASE

MESSAGE US YOUR TRACKING NUMBER

(within the 7 days from data of purchase) to ensure your purchase is not cancelled.

As required by law, the hydrostatic transmission (i.e. – “hydrostat") must be

fully

drained of oil before shipping. Please ensure that hydrostat is bagged in plastic to deter any residual oil from exiting the shipping container. We have provided pictures in the item description showing how we typically package these units. Please ensure hydrostat is packaged securely and appropriately. We recommend insuring your package through the carrier!

DO NOT SEND RESERVOIR WITH UNIT!

When shipping your unit to us, we recommend using FedEx or UPS Ground shipping

(we

DO NOT

recommend using USPS!!

). From our experience, shipping costs generally range between and , pending on the origin and shipping service chosen.

Lastly, please be certain to include a return shipping address on/with box.

If expedited return shipping is required, please message us. You will be charged separately for the upgraded shipping service. Your cost for this option will be the difference of the

FREE RETURN SHIPPING

we provide and the cost of expedited delivery.

Warranty

As much as we would like to give a warranty, we cannot, because we have no control over where, how, when and why this unit is installed. This unit is

re-manufactured

to replace an existing unit in the same application that the existing unit was used in the first place. At the same time,

customer satisfaction is of utmost importance to us!

In the unlikely event you have any issues, please do not leave negative feedback! Instead,

please contact us so we can resolve any issues

.

You will find us pleasant to work with.

How do I determine the ROTATION of my Hydrostat?

1

)

All EATON hydrostats are stamped with either "CW" or "CCW" on the aluminum casting just below the Input Shaft. For example, if the unit you are sending is stamped with a "CW", then you will need to order a "CW".

2) Another way to tell is when facing the hydrostat from the side with the input shaft, look at the fan to determine what direction it must turn to blow air over the unit. If the fan must spin CCW to do this, then your unit is a CCW.

Have more Questions?

If you have any questions about the hydrostat, rebuild process, shipping or otherwise, please don't hesitate to get ahold of us!

We are now rebuilding EATON Model 770/771 Hydrostatic Drive Units as well! -->

https://www.ebay.com/itm/323796151746